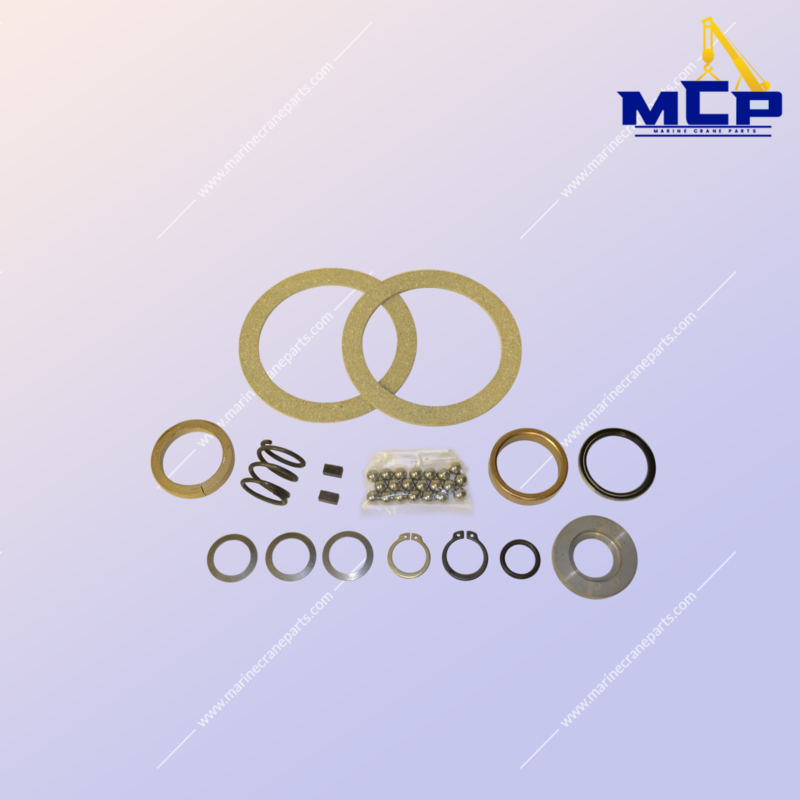

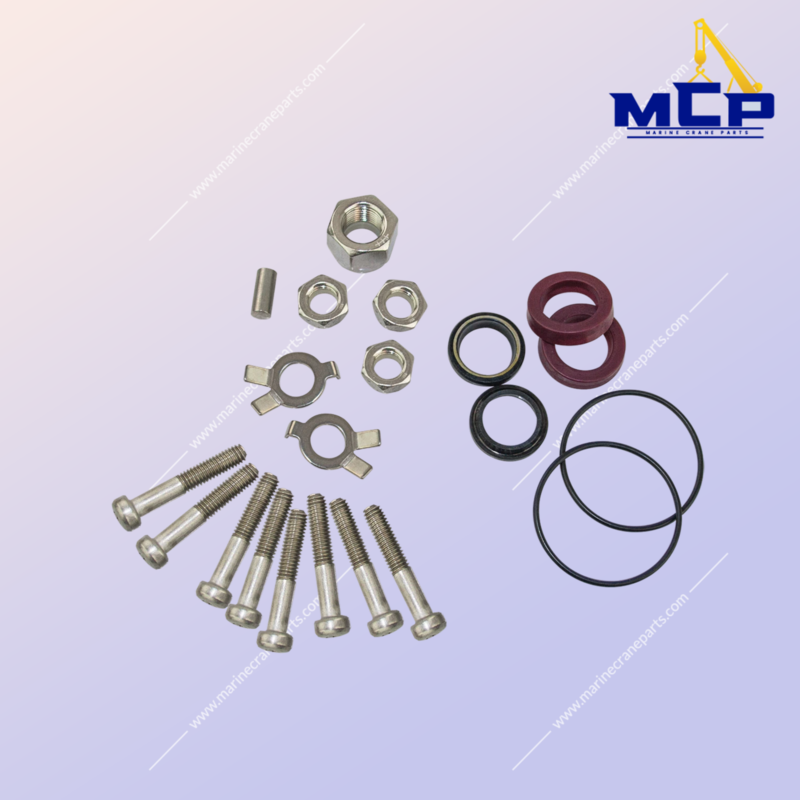

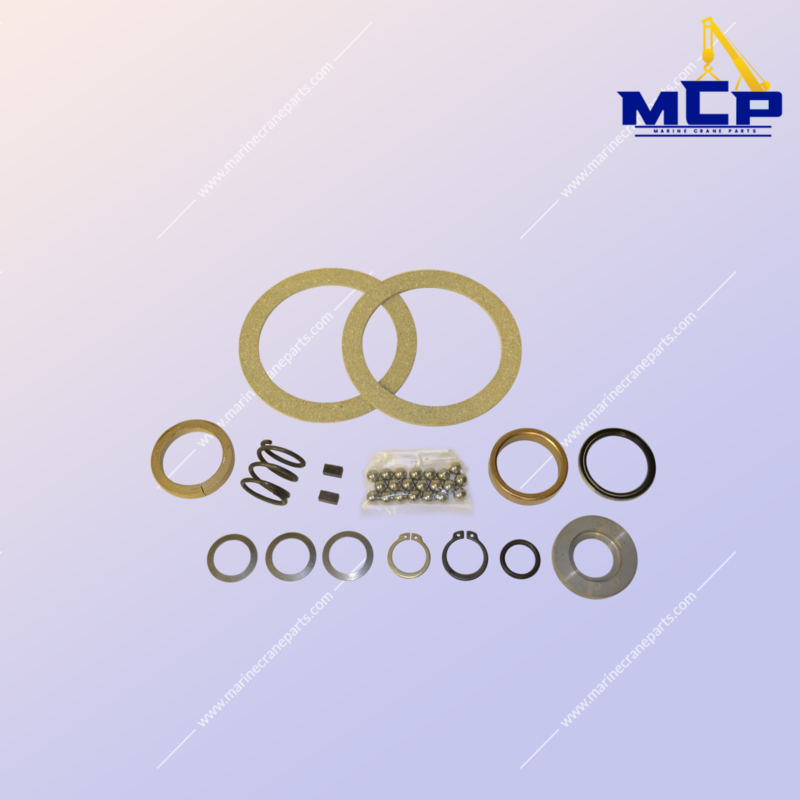

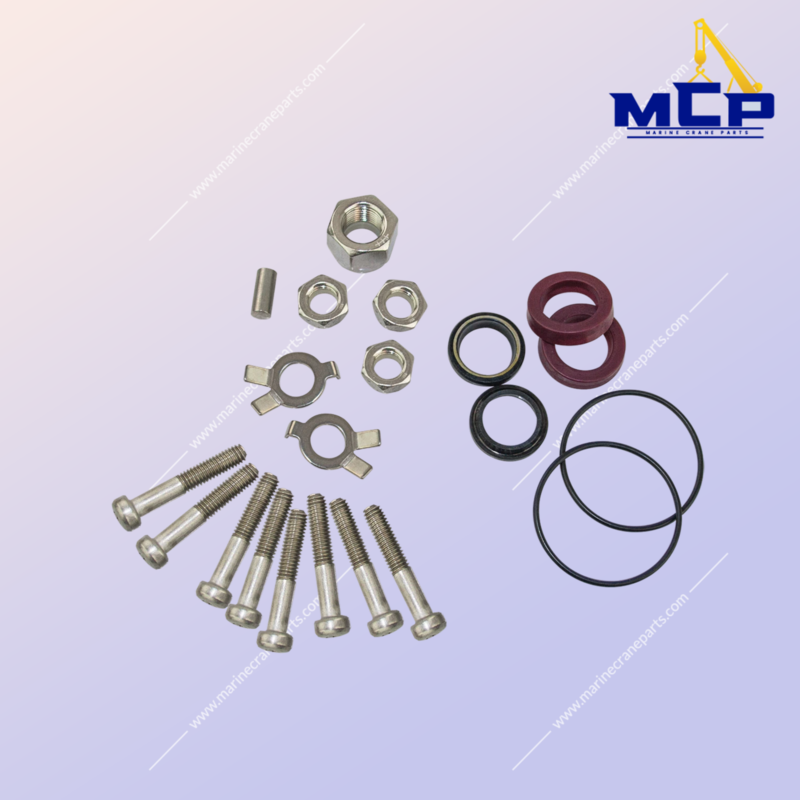

Winch Seal Kits

Seal kits used on marine crane winches are specifically designed to withstand the harsh conditions of marine environments. These seal kits help protect the winch components from saltwater, humidity, and other corrosive elements that are common in maritime settings. The types of seals used in these kits may vary depending on the specific winch design and application, but some common types of seals found in marine crane winch seal kits include:

Lip Seals:

Lip seals, also known as oil seals, are commonly used to prevent the entry of water and contaminants into the winch gearbox. They consist of a flexible lip that makes contact with the rotating shaft, creating a barrier against external elements.

O-Rings:

O-rings are circular seals made of rubber or elastomeric materials. They are used to create a watertight seal between components, such as between the winch housing and covers, preventing water ingress.

V-Rings:

V-rings are flexible rubber or elastomeric seals shaped like a V. They are often used in rotary applications to provide additional protection against dust, water, and contaminants.

Face Seals:

Face seals, also known as mechanical seals, consist of two flat faces pressed together to create a barrier against leakage. They are often used in more demanding applications where high-pressure sealing is required.

Teflon Seals:

Teflon seals or PTFE (polytetrafluoroethylene) seals are known for their chemical resistance and low friction. They may be used in specific applications within the winch to provide reliable sealing.

Labyrinth Seals:

Labyrinth seals consist of a series of grooves or channels that create a tortuous path for contaminants, preventing them from reaching critical components. These are effective in preventing water and debris ingress.

Flange Seals:

Flange seals are used at the joints and connections in the winch structure to prevent water from entering through gaps or seams.

High-Performance Seals:

Some marine crane winches may use high-performance seals that are specifically designed to handle extreme conditions, such as those made from materials resistant to corrosion and degradation in saltwater environments.

It’s important to note that the choice of seal types may vary based on the specific design and requirements of the marine crane winch. Regular inspection and maintenance, including the replacement of worn or damaged seals with appropriate seal kits, are crucial for ensuring the continued reliability and longevity of marine crane winches in maritime applications.

Reviews

There are no reviews yet.