Load Monitoring System

A Load Monitoring System (LMS) for marine cranes is a specialized technology designed to accurately measure, display, and manage the load being lifted by the crane. This system enhances safety, prevents overloading, and provides operators with real-time information to optimize lifting operations. Here’s a brief description of the key features and functionalities of a load monitoring system for a marine crane:

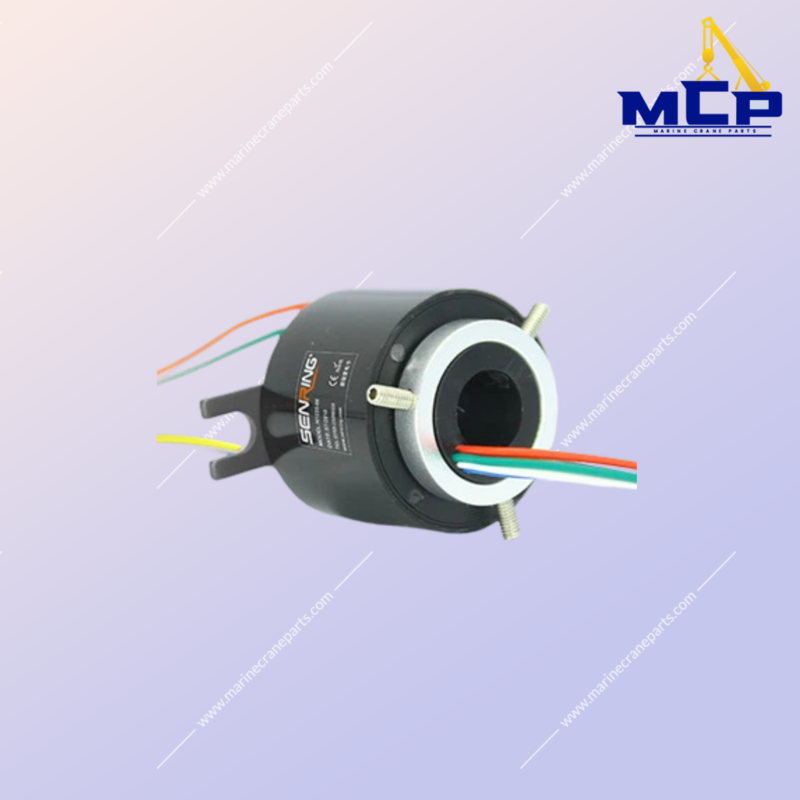

- Load Sensors: Load monitoring systems incorporate sensors strategically placed in critical areas of the crane, such as the hook, boom, or lifting cables. These sensors are designed to measure the load being lifted and transmit real-time data to the monitoring system.

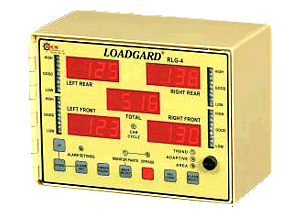

- Load Display and Visualization: The system typically includes a display unit that shows the operator the current load weight, offering a clear and real-time visualization of the lifting operation. This information helps operators make informed decisions and ensures that loads are lifted within the crane’s safe working limits.

- Alarm and Warning Systems: Load monitoring systems are equipped with alarms and warning indicators that alert the operator when the load approaches or exceeds the safe working load. These alerts may include visual signals, audible alarms, or even haptic feedback on the control interface, ensuring prompt attention to potential safety concerns.

- Load Limiting and Control: Some load monitoring systems have load limiting capabilities, automatically restricting the crane from lifting loads beyond predetermined safe working limits. This feature prevents overloading and helps protect the crane and its components from excessive stress.

- Data Logging and Recording: Load monitoring systems often include data logging capabilities, allowing for the recording of load data over time. This data can be useful for analysis, maintenance planning, and compliance reporting, providing a historical record of lifting operations.

- Integration with Crane Controls: The load monitoring system is integrated into the crane’s overall control system. This integration ensures seamless communication between the load monitoring sensors and the crane’s operating components, enabling coordinated responses to load variations.

- Calibration and Accuracy: Load monitoring systems undergo precise calibration to ensure accuracy in load measurement. Regular calibration checks may be performed to maintain the system’s reliability and precision over time.

- Wireless Connectivity: In modern marine cranes, load monitoring systems may incorporate wireless connectivity, allowing operators to access load data remotely. This feature can be especially valuable for real-time monitoring, diagnostics, and data analysis.

- User-Friendly Interface: The user interface of the load monitoring system is designed to be user-friendly, providing operators with intuitive controls and clear visual feedback. This interface allows operators to monitor and control lifting operations efficiently.

- Environmental Resistance: Considering the harsh marine environment, load monitoring systems are often designed to be resistant to water, corrosion, and other environmental factors. This ensures the system’s durability and reliability in challenging conditions.

In summary, a Load Monitoring System for marine cranes is a critical component that enhances safety, efficiency, and maintenance practices. By providing real-time load information and implementing safety features, the system contributes to the overall reliability and performance of marine crane lifting operations.

Reviews

There are no reviews yet.