Marine Engineering Systems & Design Management

With MCP’s services, we can optimize the engineering processes, shorten project timelines, reduce costs, improve the utilization of their resources and—ultimately—jumpstart the efficiency. Our analysis and designs come with PE stamp.

In today’s market, regulatory codes and standards are getting updating on a regular basis. We can perform the design/analysis applying the latest codes and standards.

Engineered Systems Design Management Inc

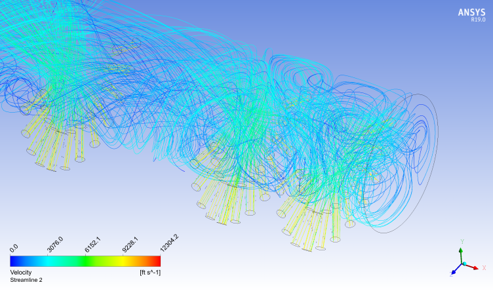

We are excited to introduce ESDM, an esteemed division of MCP (Marine Crane Parts), dedicated to providing comprehensive Engineered Systems and Design Management solutions. At ESDM, our specialization lies in a wide array of critical services essential for ensuring the integrity, efficiency, and safety of your operations. Our expertise encompasses structural analysis, CFD (Computational Fluid Dynamics) analysis, fatigue analysis, and FMEA (Failure Mode and Effect Analysis).

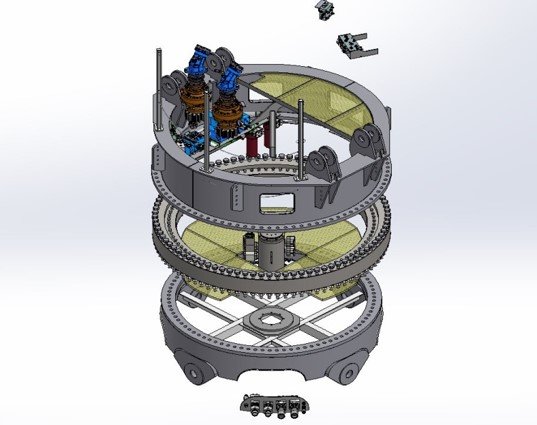

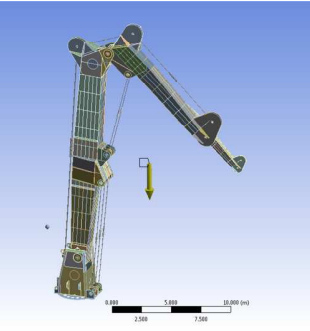

Beyond analysis, we take pride in our capability to design cutting-edge cranes tailored to meet your specific needs. Moreover, ESDM is at the forefront of securing new certifications, ensuring that our solutions adhere to the highest industry standards. With a commitment to innovation and reliability, ESDM stands as your trusted partner in advancing the capabilities of your infrastructure.

Component Design & Analysis

We have performed design and analysis work on almost every type of component that makes up today’s marine/offshore cranes, including several other other structural/hydraulic systems.

The nature of our component design and analysis work is very project-specific, but the one key attribute common to all of these projects is our client-focused approach. Whether performing detailed finite element analysis (FEA) to determine suitability of a certain design geometry, or sitting with the client to discuss conceptually their particular needs for a new component, our commitment to getting you what you need is paramount.

The close relationship between our analytical staff and our test labs is the key to our component engineering success. Our component design and analysis specialists in spend a significant of time in the test labs and understand what works in the real world. They have testing and analytical experience reaching back forty years, and real first-hand knowledge of what has and has not worked in the past. This level of information is not learned in a classroom, nor can it be quickly obtained. There is no substitute for experience.

- Structural Components of Marine Cranes

- Pedestals

- Deck winches

- Hull

- Underdeck Structures

- Welds and Fastener Connections

- Offshore Cranes and Critical Components lincluding lattice booms

- Platforms and Temporary Structures

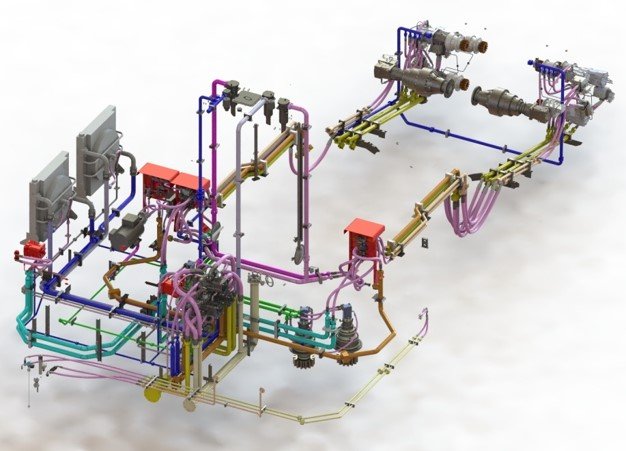

- Hydraulic Connections and Layout

- Complex Marine Structures

Engineering Services

- Innovative Designs are acheived by our customers at MCP. Complex designs including several thousand parts can be delivered by MCP including the structural analysis and regulatory approvals.

- Complex Hydraulic Layouts with 3D design and models will help the installation team and save cost in man hours. All design verification and visualization helps project planning including pipe spools and rework time.

- Detailed FEA analysis is performed at MCP to solve complex engineering problems, improve load charts and perform engineered lifts.

- CFD analyses are performed to resolve the Fluid Structure Interaction Problems, Thermal Stess Relieving Problems and Pressure Vessel Design Problems as per ASME Section VIII Div II.

- Fatigue analyses are performed to get an insight of the expected life for critical components of the crane structure. Intelligent material choices can be made to acheive the required life and design improvements can be made to extend the life.

- With on site survey, data collection and efficient CAD modeling, MCP can reverse engineer any and all marine/offshore components.